Technology

Tackling Climate Change with Electrification Technology

Maximizing Battery Pack Performance

For batteries to function as next-generation energy infrastructure, they must withstand various temperature environments. Lithium-ion batteries, with their high energy density, are gradually replacing lead-acid batteries, but challenges remain, especially concerning safety. Lead-acid batteries require 8-10 hours for charging, while conventional lithium-ion batteries can still take 2-3 hours to fully charge.

In regions with expected economic growth, motorcycles and three-wheelers remain everyday transportation options. However, in hot climates, batteries degrade at a faster rate, limiting lithium-ion battery demand to less than 3% of the overall market. Additionally, low temperatures inhibit chemical reactions, making it difficult to use these batteries in colder areas.

The lack of batteries that can endure extreme environments drives up costs due to their short lifespan, preventing those who would benefit most from electrification from accessing these solutions.

We are developing battery technology that remains stable and functional in both high and low temperatures. We've also collaborated with various companies to develop key components, such as bus bars, connectors, and chips.

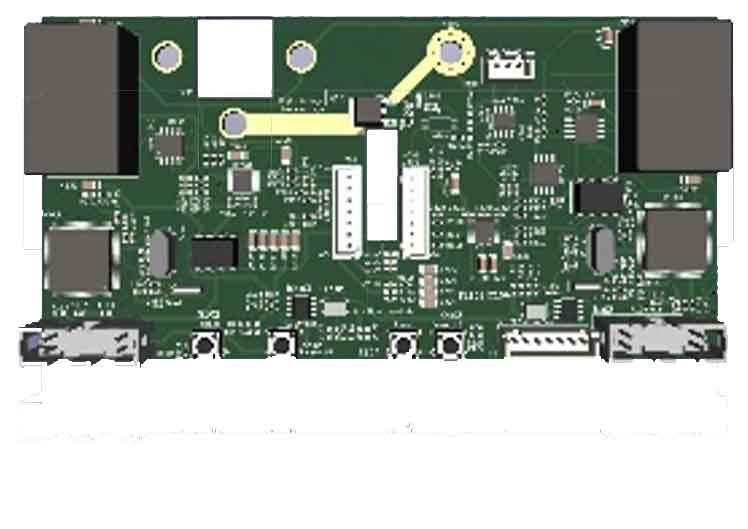

BMS and Protection Circuit Board Operating from -30°C to 60°C (Patent Pending)

We handle in-house development of circuit design, manufacturing, and embedded control software. Constant monitoring at the cell level optimizes charge/discharge cycles, ensuring efficient power usage and extended battery life.

Data processed by embedded Edge AI is sent to the cloud, allowing low-power, low-data transmission for essential research data collection, supporting battery-based business development through big data analysis.

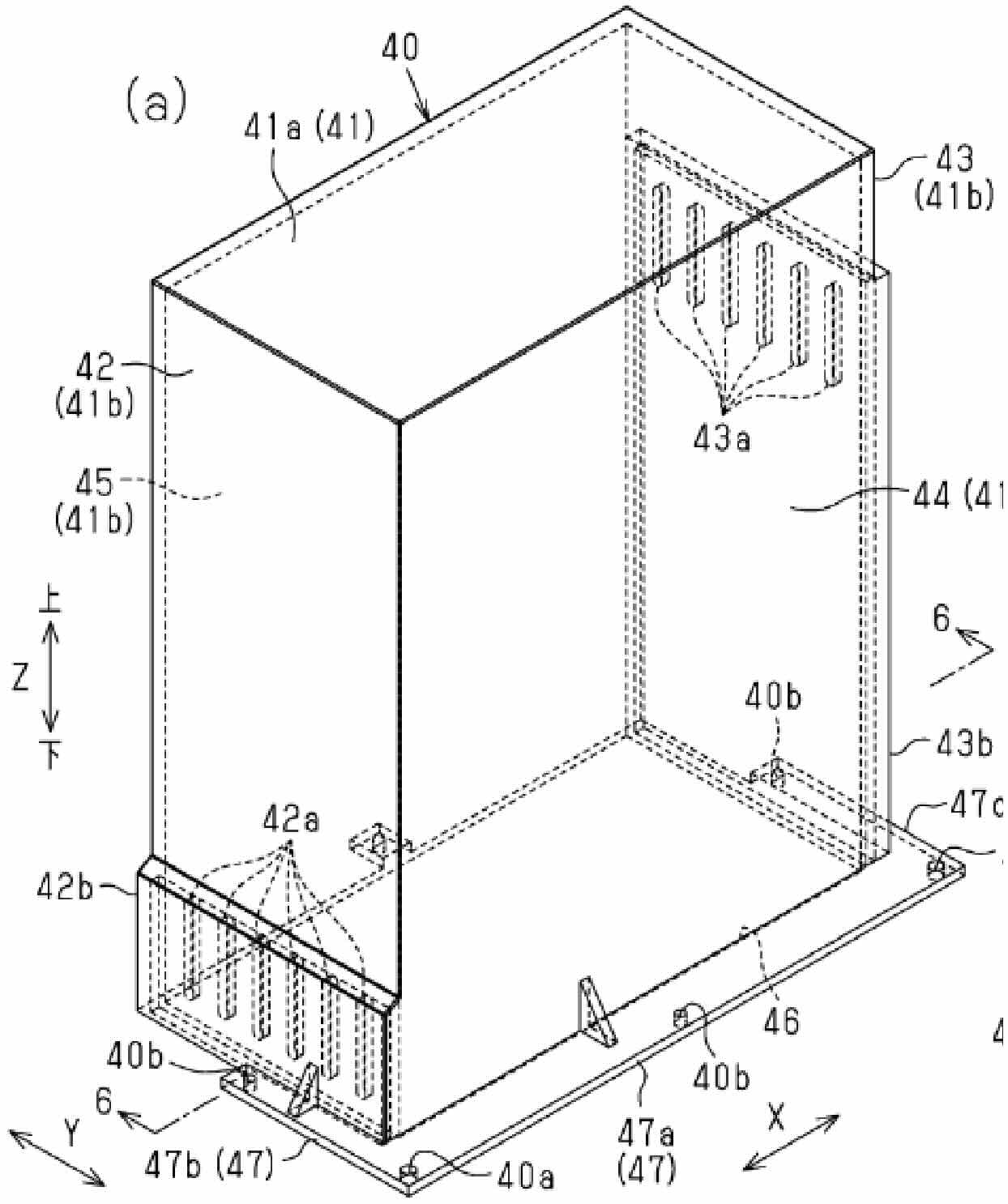

Forced Air Cooling Battery Technology (Patent Pending)

Jointly developed with automotive parts manufacturers, this technology precisely adjusts the temperature, volume, and speed of airflow into the battery pack, cooling heat sources generated by rapid charging.

We specialize in creating enclosures from resin, promoting the reuse of plastics and the use of ocean plastics.

In cases where metal enclosures are used, external antenna designs are typically required to incorporate communication functions, but this is no longer necessary. Heat dissipation methods using Peltier elements and other materials are also being explored.

Mobility Connectors for High Current Applications (Patent Pending)

When handling high currents during rapid charging and discharging, conventional connectors with few contact points generate considerable heat. Additionally, frequent plug/unplug actions wear down the metal parts, increasing resistance and further increasing heat.

This results in additional heat sources outside the battery, potentially degrading the cells and shortening their lifespan. Excessive wear can cause connector failures, ultimately shortening the battery pack's overall lifespan.

While standard connectors typically last for about 500 cycles, increasing the number of contact points can significantly reduce heat generation from high currents and lower maintenance costs.

Achieving 3-Minute Charging on Standard Power (Patent Pending)

NX Power-Amp System

Typically, rapid charging requires a power supply for industrial use. Naturenix has developed a system that enables full charging in just a few minutes for motorcycle battery packs, even from a 1,500W household outlet, with an output of 4,500-6,000W.

The charger contains an internal battery, allowing rapid charging alongside household power.

This technology is also applied in emergency power sources and smartphone chargers, where multiple users can access power simultaneously during disasters.

Customization and Subscription Options

Battery packs, unlike standard AA batteries, lack universal standards and come in various shapes depending on their use cases.

We offer replacement solutions for lead-acid batteries and lithium-ion options like LFP and MNC, ensuring safety and fast charging. We can accommodate both integration of existing battery modules and custom development.

Our expertise covers applications such as AGVs, golf carts, forklifts, and industrial robots. We also have experience designing and developing powertrains with embedded batteries for emerging markets, such as national railway electrification projects using repurposed automotive ECUs and powertrains.

Our battery packs are available for purchase in volume, but we also offer subscription and rental options, allowing equipment manufacturers to provide subscription services with minimal upfront costs.